877-558-4400

Roof Coatings

Lifetime Roof Guarantee

Get A Free Consultation

Get A Free Consultation

We will get back to you as soon as possible.

Please try again later.

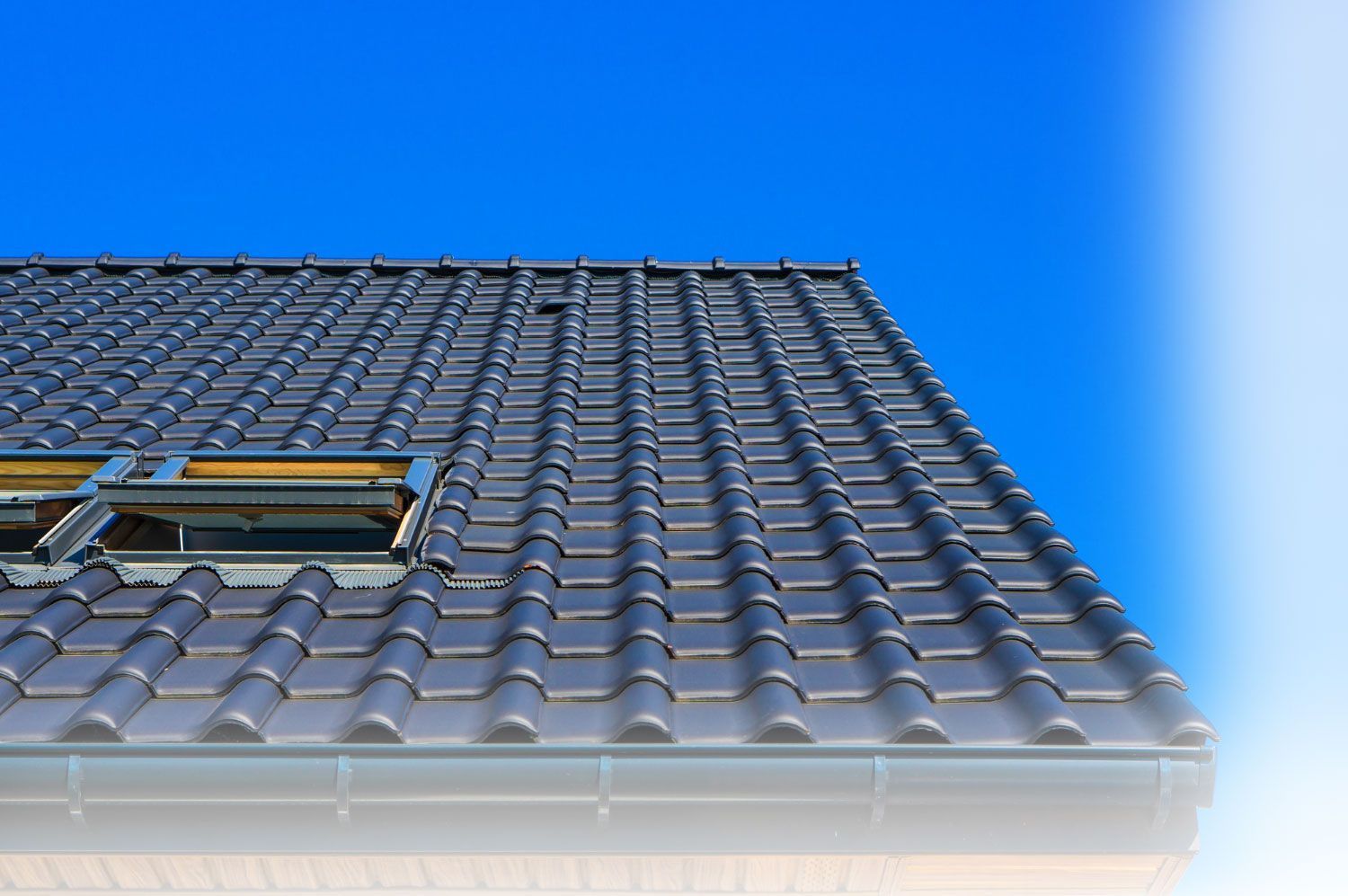

Roof Coatings In Dallas, TX

Applying a commercial roof coating introduces a protective layer to an existing roof, prolonging its lifespan at a significantly lower cost compared to a complete roof replacement. Beyond mere roof repairs, roof coatings have gained popularity among business and property owners, as well as homeowners with flat roofs.

A roof coating involves the application of a liquid sealant or coating onto an existing roof membrane. This application can be carried out through rolling or spraying the liquid across the entire surface of the existing roof. As the liquid is applied, it spreads and binds together, forming a seamless roof coating.

TIG Roofing's experts provide comprehensive roof coating services, commencing with a FREE ROOF INSPECTION. Our services include detailed documentation featuring photos and videos, including the use of a thermal camera to assess the eligibility of your commercial roof for a roof coating.

This roof coating service not only extends the lifespan of the existing roof but also transforms into an energy-efficient solution with the application of a reflective coating. The coating contributes to the creation of an environmentally friendly structure, reducing the carbon footprint. This technique has gained popularity due to its ability to contract and expand with weather changes, ensuring the roof remains protected.

TIG Roofing stands out as a premier residential and commercial roof coating company, catering to the needs of the metro Dallas, TX area.

Step 1

Free Commercial Roof Assessment

Step 2

Evaluation Analysis

Step 3

TIG Roofing Gets to Work

Reasons for Roof Coatings

Coatings are an attractive option for many Dallas, TX business owners, property managers, and homeowners with flat roofs for various compelling reasons, including:

- Seals and prevents future roof leaks.

- Extends the lifespan of your roof with a substantial warranty lasting 10-20 years.

- More cost-effective than a complete tear-off and replacement of the existing roof.

- No need for city or county permits, as a roof coating is categorized as maintenance and does not add another layer of roofing materials.

- Provides additional protection against hail and storm damage.

- Avoids expensive upgrades to meet the latest code requirements.

- Reduces energy costs, as many roof coatings have reflective properties that deflect ultraviolet (UV) rays.

- Quick installation, often completed within a few days for smaller buildings.

- Minimal to no disruption to normal business activities.

The optimal time for installing a roof coating is before signs of issues such as minor leaks, lifting or loose seams, or damaged flashings like pipe jacks with cracks or noticeable tears, which can allow water inside the building. If any of these issues have already occurred, commercial flat roof repairs must be addressed by a roofing contractor before initiating a coating project.

Flat Roof Repair and Metal Roof Coatings

The roof coating application consists of three main installation steps: surface preparation, including repairing and sealing all seams, applying a primer coat, and the actual coating application.

Flat roof inspection: Once you contact us to schedule a flat roof inspection, we will have several questions, including:

- Does your building have any active roof leaks?

- When was your commercial roof last inspected or repaired?

- What is your roof’s age?

- What type of roof material is currently installed?

- What is the approximate size of the roof in square feet?

- How many stories is the building?

Once we capture this essential information, we will schedule a free roof inspection.

Commercial metal roof coating: Metal roof coatings offer numerous advantages, going beyond mere leak prevention. They efficiently reduce energy consumption, safeguard against rust and corrosion, decrease maintenance expenses, and prolong the roof's lifespan. Notably, they come at approximately half the cost of traditional roof tear-offs and replacements.

However, when faced with the task of selecting the optimal metal roof coating for your building, a plethora of suitable options may leave you uncertain. How do you make the right choice? It proves beneficial to grasp the most prevalent issues that typically arise on commercial and industrial metal roofs.

Problems Affecting Metal Roofs

Coating systems face several challenges when applied to metal roofs. One primary concern is the propensity of metal roofs to develop leaks. Despite the inherent durability and longevity of metal as a roofing material, leaks can still arise due to compromised seams or loose fasteners. This issue is often attributed to the natural expansion and contraction (thermal movement) of the roof structure.

Corrosion and rust represent common occurrences on commercial metal roofs. While distinct processes, both corrosion and rust are essentially chemical reactions that contribute to the breakdown of materials. This poses a long-term concern, weakening roof panels and ultimately leading to premature system failure.

Our Services

How We Can Help You

Roof Coating FAQs

-

What kind of roofs can be coated?

Almost all types of roofs can be coated. Some examples include metal, spray polyurethane, single-ply, modified bitumen, Built-up roof (BUR) systems, etc. Without special treatments, ballasted and gravel surfaced membranes are not typically acceptable roof surfaces for coating membranes.

-

What are the energy savings?

This depends on the geographic location, insulation, and cost of electricity. Lawrence Berkeley National Laboratory (LBNL), Oak Ridge National Laboratory (ORNL), National Roofing Contractors Association (NRCA), and several roofing material manufacturers have computer programs that can estimate the savings. A growing number of energy consultants are available to provide environmental regulation compliance information.

-

How long will the coating last?

Based on long-term histories, typically the roof life of a properly applied roof coating can be extended up to 10 years or more. Performance can vary depending on type and conditions, as well as the coating film thickness.

-

Can I coat a Rusted metal roof?

Rusted metal roofs can be coated after the rust conditions have been addressed. If the roof is “white rust” (zinc or aluminum) it can be coated after cleaning. If the roof is “red rust” the rust must be removed or treated with a corrosion inhibiting primer. All rusted fasteners should be treated or replaced.

Dallas Metro Area Roofing

If You Want Quality Service And Professionalism

Get A Free Consultation

We will get back to you as soon as possible.

Please try again later.

24-7 Assistance

all us anytime 24/7 to schedule a crew to come out and assess your situation.

Financing Options

When it comes to financing your roof replacement or repair, we believe in a sensible approach. We offer payment plans that are easy on your wallet and your credit score.

Free Estimate

We think you should have the opportunity to make a well-informed, responsible decision when it comes to upgrading the roof over your home or business.

Corporate Office

13355 Noel Road, Ste 1100

Dallas, Texas 75240

3010 LBJ Freeway Ste 1200

Dallas, Texas 75234

Company

About Us

Services

Gallery

Testimonials

Office Hours

Monday – Friday – 08:00am – 5:00PM

Saturday – (Closed)

Sunday – (Closed)

Corporate Office

113355 Noel Rd Ste.

Dallas, TX 75240

3010 LBJ Freeway Ste 1200

Dallas, TX 75234

info@tigroofing.com